- Have any questions?

- +91 98244 89119

- info@pvcthreadingmachine.com

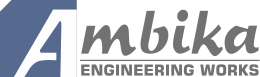

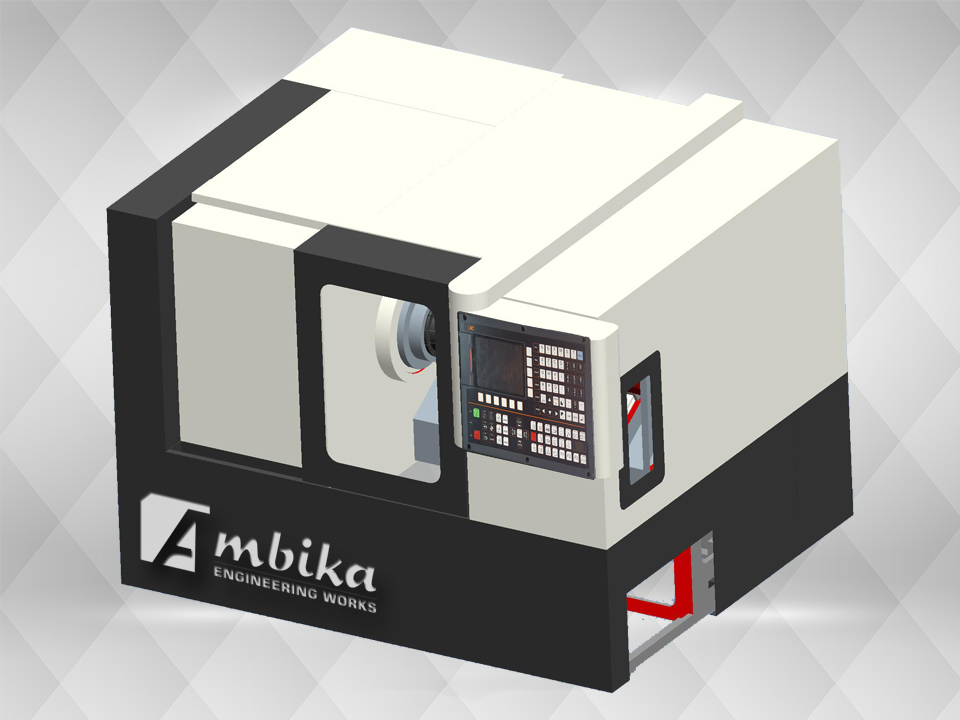

CNC PVC Pipe Threading Machine

Need of CNC PVC Pipe Threading Machines for Pipe Manufacturers

Pipe threading is necessary when you are repairing or updating pipes of old homes. The modern pipe threading machines are convenient portable units, which are relatively inexpensive as against their previous versions.

There are some specific advantages of using threads and they are listed below:

- The non symmetrical parts can be machined without hassles

- Users do not have to worry about the upper limit to internal and external diameters

- A single clamping set up can accommodate almost all the operations

- Short chips meant for simple control

- Surface finish of superior quality

- The blind holes do not need a thread relief groove

- Presence of interchangeable inserts

- Large diameter tap threading needs lesser power than the taps do

- A single insert can be designed for a wide variety of work piece materials

- The interrupted cuts are machined without any special condition

- A very limited range of tooling units is adept at covering a very wide range of applications that results in major lowering of the tool inventory costs

The benefits of using automatic and semi automatic pipe threading machines

Automatic and semi automatic pipe threading machines are devices that are used for creating thread designs observed in the pipes used for a wide range of applications. The thread designs allow the pipe to be properly screwed and connected to the component for which it is used. For example, if a pipe is used for the purpose of water supplying, then the thread assists in connecting the pipeline to the primary water reservoir.

There are several benefits of using automatic and semi automatic CNC pipe threading machines. Some of them are below:

- The automatic and semi automatic PVC pipe threading machines helps to maintain uniformity while cutting the threads in the pipes.

- Threading only one end of a pipe is not deemed sufficient in many cases and for optimum results both the ends of the pipes has to be threaded. In such instances, the automatic and semi automatic pipe threading machines can be highly useful. By using these machines, one can get the same types of threading at both ends of the piping systems.

- These machines can also be used to create customized thread designs that are more user-specific in nature.

- Most pipe manufacturing companies produce piping systems in bulk, and these machines can assist in cutting of threads very quickly and conveniently.

- While the earlier models of automatic and semi PVC automatic pipe threading machines were slow in their operations, advancements in technology have led to the development of machines that can not only produce threads and cuts of high efficiency but can be used for bulk productions as well.

- As the maintenance costs for automatic and semi automatic PVC pipe threading machines are very low, it allows people to use them for many years with little or no technical glitches. Moreover, these machines deliver a high rate of production in low output, which allows in saving manufacturing costs.

- There are a wide variety of pipe threading machines currently available in market, which provide users with plenty of options regarding the same. Both large and small models of automatic and semi automatic pipe threading machines are available; each of these models caters to a wide range of functions. The machines are not only easy to transport or store but also quite convenient to use.

CNC machines for handling all your pipe threading needs

A CNC casing pipe threading machine, CNC pipe threading machine or a column and casing pipe threading machine is a tool that is used for making the thread design that occurs at the terminal end of a section of a pipe. These machines allow in producing pipe threads of high quality; i.e. that are uniform and smooth in nature. CNC machines also allow the users to develop pipes that have custom thread designs and also pipes that are comprised of universal threads.

There was a time when the column and casing pipe threading machines were predominantly used by the large scale manufacturers and developers who mainly focused on the mass production of threaded steel pipes of different sizes. Apart from carving a specific thread design, these CNC machines also helped in dissecting the pipes in smaller, more workable sections. The machines also helped to ream out the differently sized pipes in order to make sure that no problems arose within the structure of the main pipes. The procedures used for cutting and threading pipes were increasingly refined over time, which made it possible to develop the finished products quickly and send them for sale in the markets within a short period of time. Apart from guaranteeing that the efficiency of production will be increased by several notches, the various latest models of column and casing pipe threading machines also require less maintenance than what was needed for the older models.

Most of the latest models of column and casing pipe threading machines are designed in a way that they can be used to cut or thread materials other than standard metallic ones. The pipes that are constructed out of plastic or resin materials can be easily worked on by the latest CNC threading machines. The users do not even have to worry about technical issues such as overheating or damages that can possibly occur to the finished goods. There are numerous developers and manufacturers that use CNC machines like these to prepare low-cost plastic pipes having thread configurations which are recognized universally.

There is now a growing demand in India for column and casing pipe threading machines that are of high quality and guarantee efficient production of finished goods. Due to this, numerous young entrepreneurs in this country have come forward to invest in this industry and produce CNC machines of varying parameters and capacities. If you are looking to buy a CNC pipe threading machine for your business, you would be pleased to know that there are plenty of manufacturers and dealers right now for you to choose from. Before you finally settle on a manufacturer or supplier to purchase a CNC casing pipe threading machine, it’s necessary for you to decide on your specific requirements and budget parameters; this will allow you to easily find out who has the machine that blends with your priorities perfectly. However, you should not always try to find low budget deals only, as that will eventually make you end up with a CNC machine of lower quality. The best thing to do would be to compare a number of brands and then finally choose one of them based on how it is reviewed by previous customers.

The importance of column and casing pipe threading machine

A column and casing pipe threading machine or a CNC pipe threading machine is a device that is used to make the thread design at the end of a pipe’s section. These machines make it possible to produce pipe threads that are smooth and uniform in nature. They also allow users to create pipes that are equipped with custom thread designs as well as pipes that are developed with universal threads.

At one point of time, CNC pipe threading machines were exclusively used by large scale manufacturers who primarily focused on mass production of differently sized threaded steel pipes. Apart from carving the specific thread design, the CNC machines would also dissect the pipe into smaller, workable sections and also ream out the pipes to make sure that there were no problems within the main pipe. Over time, the procedure for threading and cutting pipes were more and more refined, thus making it possible to come up with finished products for sale within a very short duration of time. Not only have the latest models of CNC pipe threading machines increased the overall efficiency of production; they also require much less maintenance than the older models.

The latest models of CNC pipe threading machines are also designed to cut materials other than the standard metallic ones. Pipes that are made of resin or plastic materials can now be worked on by these CNC threading machines without any worrying about overheating or damage caused to the finished products. There are numerous manufacturers that use these machines for preparing low cost plastic pipes by using the thread configurations that are universally recognized.

As the demand for high quality column and casing pipe threading machines have increased over the last few years, numerous companies all over India now produce these machines of different capacities and parameters. Before finally choosing a manufacturer from whom you can buy a CNC pipe threading machine, it is important for you to consider your specific needs and budget parameters, as that way you will be able to find out easily who has the product that matches your priorities. It is also very important not to go overboard with a low budget approach. While saving on costs will definitely be one of main priorities, insisting too much on lower rates may make you end up with a product that does not ideally match your expectations. The best way to make a purchase would be to compare a few brands and then choosing one of them as your final dealer.

Borewell PVC Pipe Threading Machines

Borewell is basically a narrow hole constructed to reach underground. They are constructed for several purposes but the main logic is to reach and extract any kind of liquid like petroleum or water or gas from underneath.

Once the hole is constructed normally a pipe is passed in so that the liquid or gas can flow through it to reach its destination. This pipe is connected to the main reservoir where the liquid is stored before supplying it to various locations. Thread in pipes makes the process of connecting it to the main component easy and the borewell pipe threading machines are used for the purpose. Here are some benefits of using threading machines.

- These machines helps in maintaining uniformity when cutting thread. If the threads are uniform then the installation will be easy because normally when borewells are deep and it becomes difficult for people to get in and make sure that the work it perfect. Most of the underground work is done with the help of camera which is dropped in.

- There can also be situations when you might need a connector and to install it you will want to have threads on both side of the pipe. Borewell pipe threading machines make sure that same type of threading is done on both the ends.

- If you are planning of something new and you need a customized thread design then these machines are perfect. They are capable of providing customized thread design.

- If you are a borewell pipe manufacturer then these machines will be quite helpful to you, especially when attending to bulk orders. Earlier machines were slow but with advancement in technology the machines used today are highly efficient and you can even finish huge orders.

- A wide variety of borewell threading machines are available in the market. You can either go for a fully automatic or semi automatic version depending on your comfort and affordability. You can buy these machines online or offline from authorized stores. When you buy online you must make sure that you do adequate research regarding the company, its product quality and also the price. Do not just run behind companies offering the lowest quote. Make sure that the price of the product is compared with the quality and service they are offering.

Automatic PVC Pipe Threading Machine

Pipe threading machines are used to create thread design that you see in pipes used for various applications. These thread design helps the pipe to screw and connect to the main component it is used for. For example if the pipe is used for water supplying than the thread connects the pipe to the main reservoir where the water is stored.

There are many benefits of using the machine and some of them are:

- The automatic PVC pipe threading machine allows maintaining uniformity when cutting threads in pipe.

- There can be a situation when thread at just one end of the pipe will not be enough and you will want to have it on both the ends. Here this machine will be very useful. You can have same type of thread at both the ends of the pipe.

- You can also create custom thread design with the use of automatic PVC pipe threading machine.

- Most of the pipe companies manufacture in bulk and the machine helps them cut thread quickly.

- The machine not just carves thread in the pipes but it can also be used for cutting it in required size pieces.

- Earlier the machines were slow but with the advancement in technology the machines have also improved and now they not just come with high efficiency level but they are also used for huge production.

- The maintenance cost of these machines is also low. Thus you can save money when considering the total manufacturing cost.

- Wide variety of threading machines is available in the market and you can buy one depending on your requirement. You can go for a fully automatic pipe threading machine or a semi automatic version. Along with large machines for industrial use you will find small portable threading machines in the market. These machines are easy to store and also can be carried to any project location. The small threading machines are mostly used in construction sites by professionals for plumbing purpose. The portable version is also good to be used in homes.

Buying automatic PVC pipe threading machine is not difficult because when you browse online or venture into the market you will find a lot of companies dealing with such machines. But, in order to make sure that the machine quality is good you need to do some homework in form of research. You can check online and collect all the required details of different companies specialized in manufacturing and selling pipe threading machine. Compare their prices and then buy from the one that suits your need.